PRODUCTS

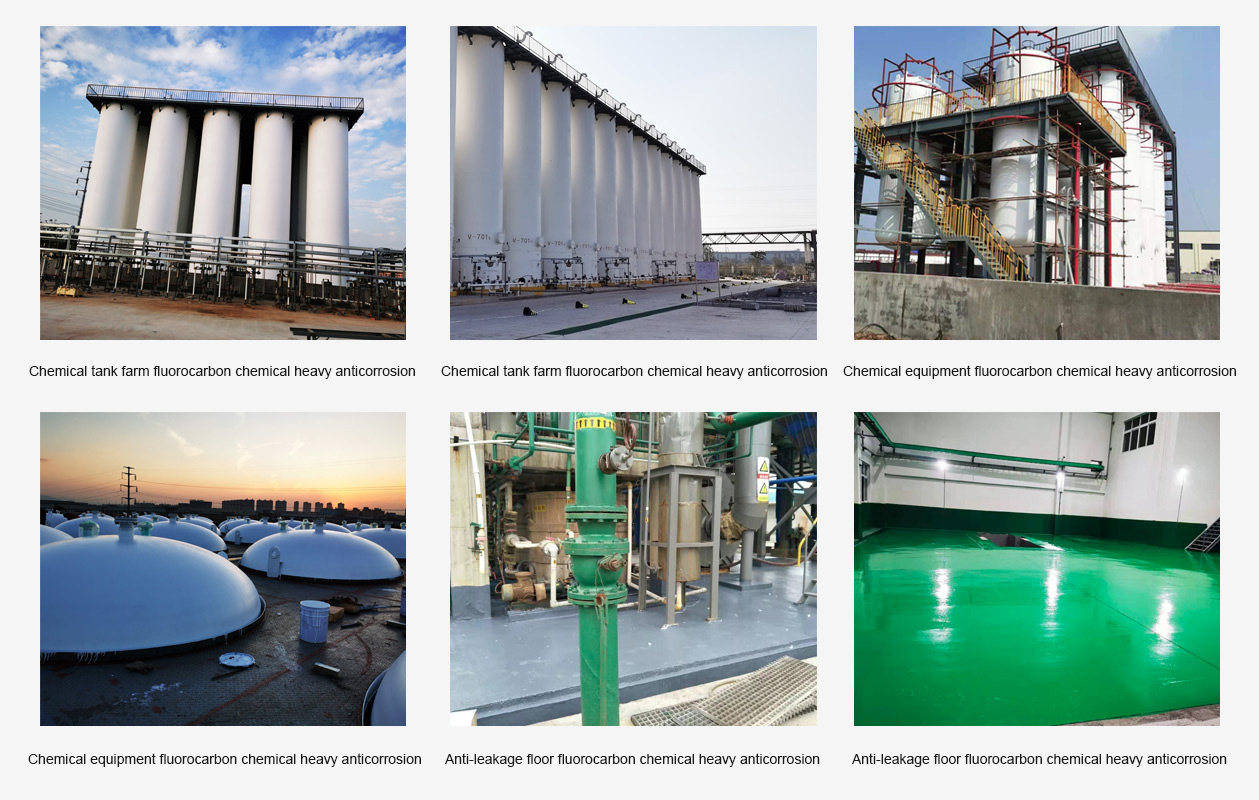

Product introduction: This product is made of fluorocarbon resin, high-quality pigments, fillers, BYK and other excellent additives. It is a two-component reactive coating with Bayer curing agent to form a film. It can effectively prevent the base surface from being damaged by various corrosive media and prolong the service life of the coated object.

Uses: Suitable for anticorrosion of urban landmark steel structures, large bridges, ships, chemical plants, and power plant steel structures that are difficult to maintain.

Features: The so-called heavy anti-corrosion is generally understood as the environment where the steel structure or equipment is very harsh, the maintenance is very difficult, and the chemical pollution is serious. Matching anti-corrosion methods must be adopted. The coating used to meet this requirement is the key. The product has super weather resistance in hot and humid environments, and has good corrosion resistance and usability in environments with acid-base salt concentrations below 10%.

Construction method: deployment in strict proportion. First mix the curing agent and the paint thoroughly and cure for 15 minutes, then add the thinner. In the production process of this product, special consideration is given to the construction requirements, so it can be painted by brush, spray or roller. The supporting special topcoat construction generally adopts the construction technology of two bottoms and two sides or two bottoms and three sides. This product is a two-component reactive coating, which should be used within 4 hours after mixing.

Drying time: temperature 25 ℃, surface dry 30 minutes, hard dry 24 hours. Fully cured for 5-7 days.

Coating interval: more than 4 hours.

Storage: Cap tightly sealed. Store in a cool, clean, dry place. The shelf life is 2 years.

Surface treatment: remove floating rust and welding slag spatter on the surface of the workpiece, and carry out dust and oil removal.

Construction conditions: The humidity during construction is less than 75%, and the construction temperature is 5°C-40°C. Construction is strictly prohibited in rainy, snowy and foggy weather.

Safety and Precautions: Ensure that the construction site has good ventilation. Keep away from open flames, no smoking at the construction site, and avoid paint splashing on eyes and skin.

Supporting primer: anti-corrosion special primer

Table 1 Chemical medium resistance performance of fluorocarbon coatings

| Item | Result | Item | Result |

|---|---|---|---|

|

Sulfuric acid (10%) |

no change in March |

Gasoline resistance (72d, 60°C and room temperature alternately) |

no change |

|

Sulfuric acid (40%) |

no change in March |

Daqing crude oil (122d, 60°C and room temperature alternately) |

no change |

|

Nitric acid (10%) |

no change in March |

Glycerin antifreeze (43d, alternate between 60°C and room temperature) |

no change |

|

Phosphoric acid (10%) |

no change in december |

Dimethyl phthalate (30d, same conditions as above) |

No significant changes |

|

Acetic acid (10%) |

no change in december |

Alcohol (50%, 112d, room temperature) |

No significant changes |

|

Sodium hydroxide (10%) |

7d no change |

Phosphoric acid (85%, 50°C, 30d) |

No significant changes |

|

Ammonia (10%) |

7d no change |

Dichloroacetic acid (room temperature, 60d) |

No significant changes |

|

Sodium carbonate (10%) |

no change in december |

Bromine (room temperature, 60d) |

No significant changes |

|

Formaldehyde (37%) |

September no change |

Calcium chloride saturated solution (75°C, 53d) |

No significant changes |

|

Seawater (100%) |

September no change |

Saturated solution of sodium carbonate (75°C, 53d) |

no change |

|

Ethanol (95%) |

no change in March |

Potassium dichromate saturated solution (75°C, 53d) |

no change |

|

Toluene (100%) |

>No change in March |